Protection Features

- Phase sequence protection

- Malfunctioning of pressure and temperature sensor

Frost Protection - High discharge air temperature/pressure

- High system pressure and temperature

- Main Motor /fan motor overload

- Main motor and fan motor current monitoring

- High motor temperature

- Low oil pressure

- Input power supply fluctuation

Service & Maintenace Prompts

- Alarm/trip history records

- Motor service & maintenance time

- Compressor service & maintenance time

- Oil filter service & maintenance time

- Lubricating oil service & maintenance time

- Oil fine separator service & maintenance time

- Air filter service & maintenance time

KSRengineers Service Kits include all genuine parts and wear parts for the respective maintenance and ensure optimum operation of the systems.

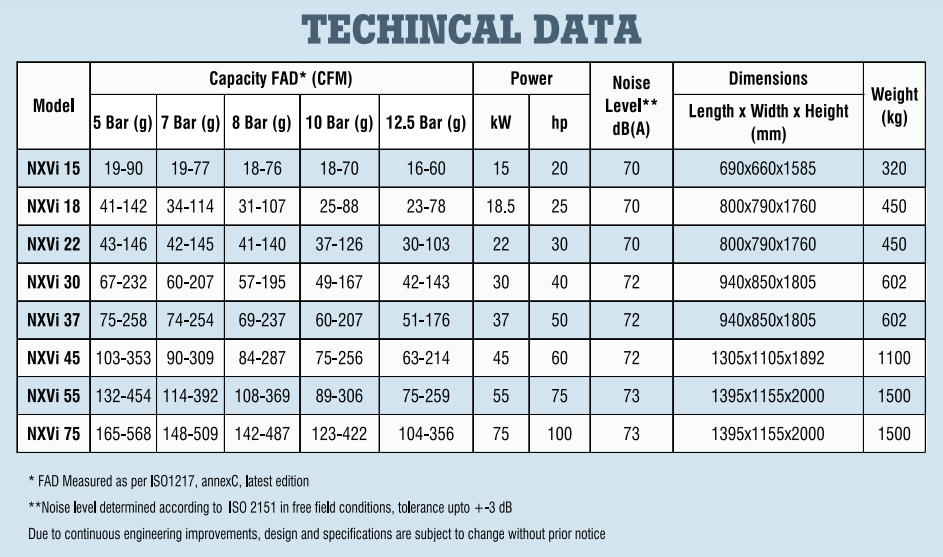

| Model | Weight (Kg) | Description |

| NXVI- 15 | 320 | Standard Filter Kit (Air/Oil) |

| NXVI- 18 | 450 | Annual Filter Kit (Air/Oil/Separator) |

| NXVI- 22 | 450 | Major Kit |

| NXVI- 30 | 602 | Screw Warranty Oil Fluid Force, 5 l |

| NXVI- 37 | 602 | Screw Warranty Oil Fluid Force, 20 l |

| NXVI- 45 | 1100 | CompAir Warranty Oil AEON S, 5 l |

| NXVI- 55 | 1500 | CompAir Screw Warranty Oil AEON S, 20 l |

| NXVI- 75 | 1500 | CompAir Screw Warranty Oil AEON S, 20 l |

FS-Curtis NXVi Series air compressors are renowned worldwide for their legendary reliability. Equipped with a patented advanced airend, an exceptionally efficient permanent magnet motor driven by a smart VFD, and intelligent controller, FS Curtis NXVi series delivers unparalleled perfomance in the toughest conditions.

FS-Curtis NXVi Series air compressors operate at peak efficiency even with 80% reduction in air output and an advanced PID control algorithm helps to generate stable air pressure. The compact vertical design saves valuable floor and workspace, provides easy maintenance access, and reduces total cost of ownership.

Energy Saving Service-friendly Package Design

Each component of the FS Curtis NXVi permanent magnet variable speed drive air compressor is meticulously crafted from design concept to actual application to ensure remarkable efficiency, resulting in higher energy-saving levels. The system and structure layout follows the principles of high reliability, high durability, and low noise. The NXVi series offers a space-saving smaller footprint that is easy to install and service friendly.

- Patented intake valve having high efficiency and energy-saving design reduces pressure loss, turbulence and noise.

- Air filter is made of multilayer nanocomposite material and has higher filtration levels, greater strength, longer service life, and significantly lower suction resistance.

- The separator, minimum pressure valve, and thermostatic valve are integrated, reducing the connections by up to 90%.

- Heavy-duty industrial hose assemblies have hydraulic fittings and can be reused.

- Non-asbestos gaskets with high temperature and pressure resistance are used to protect operators.

- The air inlet is equipped with a front filter screen to effectively prevent dust from entering,

ensuring the internal cleaning of the air pressure system and ensuring the reliable operation of the unit.