Compressor buyer guide

Rental compressors

Product Registration

Multibrand Compressor Spare

Request Service

Newsletter

WHAT ARE YOU LOOKING FOR?

FAS Series 4-11 KW

NxVi Series 15-75 KW

Nx Series15-90 KW

NxHE Series Two Stage 90-260 KW

EBS Series 240- 400/12

FAS Series 15-250

FSG Series 270A-1060A

FSG Series 45-185 KW

ES Series ES 5-20hp

FS Curtis EX 75A- EX- 120W Flow:- 11.8 to 17.1 m3/min 7-10 Bar, Oil free dry screw air compressor suitable for ISO8573-1 Class Zero requirement

PAP Plus

FS-Elliott’s PAP Plus® engineered compressor series combines over 50 years

Polaris

Polaris compressors combine over 50 years of operational and design experience in an extremely reliable,

ES Series 5-20 HP

Environmentally friendly and highly reliable, the Eco Scroll comes with a user-friendly control interface with an easy-to-read display.

ECO-Turbo

85 kW to 250 kW drive power at a final compression pressure

ER Series 20-160 HP

Oil free, dry screw water-cooled/air-cooled screw compressor suitable for CLASS ZERO compressed air.

VP Series Vacuum Pump 2-10 HP

Reliable and efficient VP series electrically driven single stage vacuum pumps are designed to meet the diverse needs of various industries-

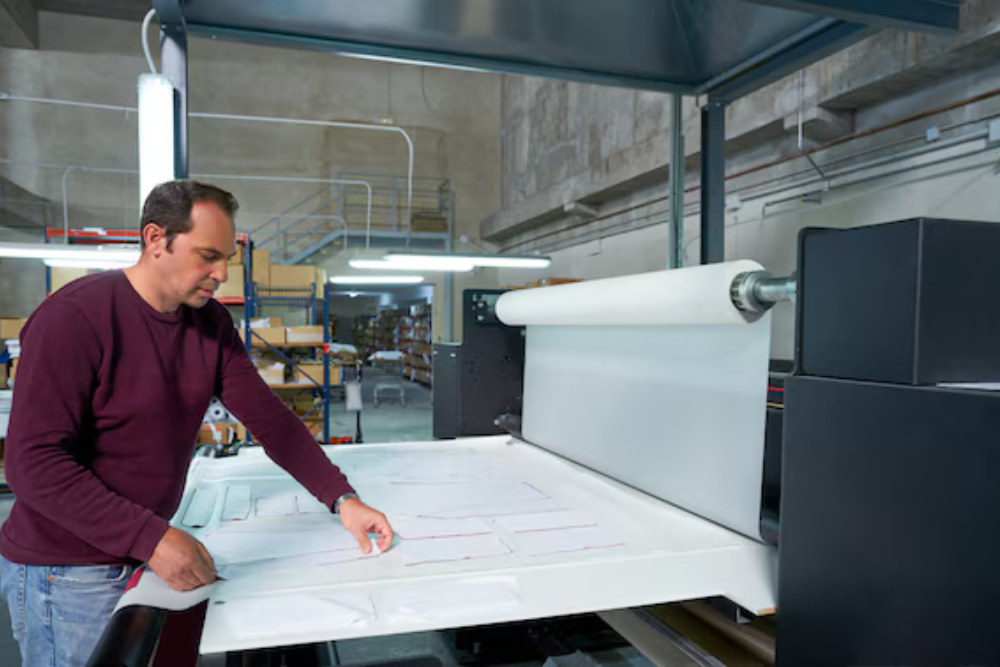

Hospitals | Laboratories | Dental | Food Processing | Packaging | Dairy | Paper & Printing | Electronics

Featured Product

Meeting Critical Needs /

CENTRIFUGAL AIR COMPRESSORS

FS-Elliott and FS-Curtis centrifugal air compressors provide you and your business with the highest quality clean, oil-free air for your compressed air application.

ECO-Turbo

Effortless Operation, Highly Efficient

The ECO-Turbo series combines decades of engineering experience from FS-Elliott partnered with the trusted and dependable reputation of FS-Curtis to bring the first in the market reliable, efficient, and innovative air-cooled or water-cooled centrifugal compressors.

The turbo compressors of the ECO-Turbo series are suitable for a wide range of applications where 100% oil-free compressed air is required with higher demand ranging from 185 kW to 250 kW drive power at a final compression pressure of up to 125 psi.

The simple and enclosed design of the compressor unit offers high reliability and ensures safe operation even under the most demanding conditions. The FS-Elliott engineered titanium impellers are designed for optimum efficiency and a long life.

ECO-Turbo compressors are easy to install, operate and maintain making them the right choice when air quality is critical for your compressed air application.

Why Choose Centrifugal Over Rotary?

When comparing centrifugal compressors to rotary compressors, centrifugal systems offer distinct advantages for specific applications. Here are the key reasons why centrifugal compressors may be preferred over rotary compressors:

Higher Efficiency at Large Capacities: Centrifugal compressors excel in providing high air volumes and pressure, making them ideal for large-scale industrial applications where high airflow is required. They are more energy-efficient than rotary compressors when handling larger capacities.

Lower Maintenance Requirements: Centrifugal compressors have fewer moving parts, reducing the likelihood of wear and tear. This can lead to lower maintenance costs and less frequent downtime compared to rotary compressors, which have more parts subject to wear.

Consistent Performance: Centrifugal compressors maintain stable, reliable performance even under varying load conditions. This is beneficial for industries where air demand fluctuates.

Better for Continuous Operation: Centrifugal compressors are designed to run continuously, making them ideal for applications with constant or high operational demands. They tend to operate more smoothly in extended usage scenarios than rotary compressors, which may experience more stress under continuous operation.

Compact Design: Centrifugal compressors are generally more compact for the power they provide, making them suitable for applications where space is a consideration.

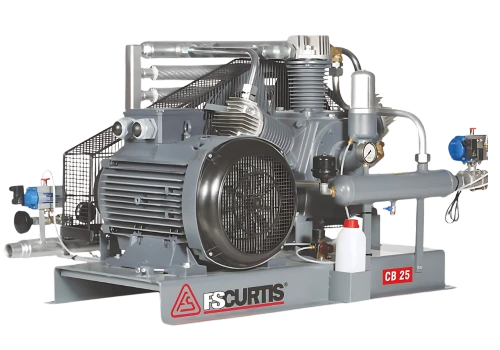

Pet Compressor

Compressed air is an energy source that is as important as electricity and hydraulics. Especially for the production of pet bottles, which are being used more and more in daily life, by people all over the world. Besides, the applications such as leak tests of hydraulic and pneumatic devices, specific drive cylinders, presses, and fixture apparatus also need high-pressure air. Unlike other applications requiring only low-pressure air, both low and high-pressure levels of air up to 40 bars ought to be used in the facilities for these applications. Therefore, instead of designing the whole system considering the high-pressure need, increasing the air pressure just at the certain points where high pressure is needed, is the most energy and cost-efficient solution.

As a manufacturer having reciprocating booster compressors in its product portfolio which boost the 7-13 bar compressed air taken from rotary screw compressors, up to 40 bars, FS-Curtis provides the most appropriate solutions with its years of experience and quality policy to pet manufacturers and the enterprises which have to use high-pressure air. These compressors can also be modified to serve as boosters for nitrogen.

One Source Compressed Air Systems

Unwanted substances are often present in compressed air due to factors such as the intake of ambient air and the process itself. These contaminants include dirt, dust, water, oil, and other micro-particles. By using an appropriate air treatment system, specifically a properly sized compressed air dryer tailored to your needs, you can effectively prevent moisture and contaminants from affecting your production efficiency and increasing costs. Furthermore, air treatment ensures that the compressed air meets the exact quality requirements of your application or process.

Effective filtration of contaminants from compressed air helps meet high air purity standards, reduces operating costs, and extends the lifespan of your equipment

Click here to read how FsCurtis compressed air treatment solutions protect your systems and processes and deliver an energy-efficient, cost-effective and environmentally-friendly solution.

Our Products For Industrial Applications

Our products offer reliability and performance across a wide range of industrial applications. From advanced compressors and air treatment systems to specialized equipment, each product is engineered to enhance operational efficiency, reduce costs, and meet the rigorous standards of diverse industries Our Products for Industrial Applications” highlight our commitment to providing robust and efficient solutions tailored to various industrial needs. Designed with precision and built to endure demanding environments

We understand that every industrial application has unique requirements, and our solutions are tailored to provide optimal performance. Our team of experts works closely with you to identify your specific needs and recommend the best products to achieve your goals. From reducing operational costs to improving productivity, our products are engineered to deliver exceptional results.

Learn more about the FSConnect

Control Systems

At the heart of every PAP compressor is the Regulus® Control System. A touch of the screen lets you control and manage the performance of one or multiple compressors, at the unit or remotely, to meet air demands while maximizing energy savings. An extensive array of optional features is available to accommodate any site.

Regulus Control Systems

Regulus Control Systems stand out with superior pressure control capabilities and unmatched flexibility to meet even the most complex system requirements. Their advanced design allows for precise management of air pressure, ensuring optimal performance across diverse applications. By eliminating excessive air blow-offs to the atmosphere, Regulus reduces unnecessary waste while responding efficiently to fluctuating facility air demands. This dynamic control not only improves operational efficiency but also empowers operators to take control of one of their plant’s highest operating expenses—energy costs.

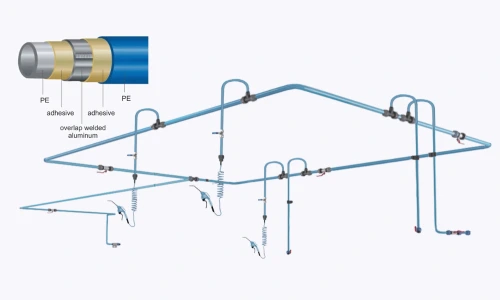

Almonium/MLC Compressed Air, Gas and Water Pipeline

Jindal Multi-Layer Composite Pipes (PE-AL-PE) combine the advantages of metal and plastic pipes and eliminate the disadvantages of both materials at the same time. They are easy to bend & install directly on girder or inside wall and cement concrete. Jindal MLC Pipes and fittings are manufactured with the latest German Technology at our state of the art facility in India.

At Jindal MLC Pipes we regularly subject our products to inspection and long-term testing. Our in house Laboratory keeps material specifications and long-term properties under constant scrutiny. This provides the necessary foundation for product enhancements performed within our Research & Development department.

As a result you will always be supplied with the highest possible quality and latest technology in the plumbing and piping system. Our range of plastic fittings is specifically designed for Indian plumbing techniques.

Who We Are

KSR Engineers takes great pride in being a trusted Authorized Distributor partner of FS Curtis, JindalTubies, Servokon harnessing its expansive local network to deliver exceptional sales, service, and support across India.

With an extensive network of committed sales companies and distributors, KSR Engineers seamlessly blends global expertise with personalized, localized service, ensuring that cutting-edge technologies are supported by unmatched assistance.

We are privileged to partner with such an innovative and forward-thinking company and eagerly look forward to the continued success of our collaboration. Here’s to many more years of shared growth and prosperity!

Your Success is Our Success

If you’re seeking an engaging and stimulating work environment, KSR Engineers could be an ideal match for you. We offer job opportunities across various functional areas, suitable for both recent graduates and experienced professionals.we aim to foster an environment where your achievements directly contribute to our collective success.We invest in continuous improvement and innovation to ensure that you have access to the latest advancements and best practices, supporting your growth and success in a dynamic environment.

Latest Updates

Enables the delivery of compressed air to the exact quality specified by the application or process.

Solutions for Industries

We are committed to delivering excellence through customized strategies, fostering industry advancements, and ensuring the highest standards of quality and reliability.

Our Story

Our dedicated team of over 40 factory-trained service personnel, each with 5 to 15 years of experience, enables KSR Engineers to address customer needs promptly and efficiently.

Founded in 2012 ksr engineers is on Authorized Distributor for Fs-Curtis Compressors, Clico, JindalTubes and Servokon in Delhi-NCR, Western UP, Uttarakhand. Led by Mr. Om Prakash Tripathi and Mr. Rajeev Tripathi, the company has experienced steady growth and expansion over the past 12 years, earning a reputation as a RELIABLE and TRUSTED partner. In 2022, we proudly celebrated our 10th anniversary, a significant milestone in our journey.

We offer premium industrial solutions to a wide array of sectors, including the power sector, food industry, textile industry, automotive, healthcare, construction, and more. This success can be attributed to our unwavering commitment to ensuring zero downtime for our customers by providing timely and high-quality support in both products and services.

Why Buy from Us?

With more than 13 years of experience, we bring unparalleled expertise and technical excellence to every project we undertake. Our committed team focuses on delivering outstanding solutions that adhere to the highest standards of quality and performance. Our work is highly specialized, addressing complex customer challenges, and we take pride in crafting innovative and sustainable solutions.

Leadership

Our executive team is committed to upholding the highest standards of integrity, providing objective, well-informed guidance, and ensuring effective oversight. We deeply value the trust entrusted to us by our shareholders, employees, business partners, and the broader community. Our focus remains on the safe, ethical, and efficient management of the company, with a strong dedication to maintaining and strengthening these relationships.

Global Reach, Local Support

While our products are designed for global industries, we focus on delivering bespoke, localized support to ensure our clients receive the attention and service they deserve.

Genuine Spare Part

As even the smallest deviation in tensile strength or dimensions of a spare part can significantly affect the operation, output, and health of your equipment, we ensure our replacement parts are made to the precise specifications of the original.

Innovation and Design Centers and factories worldwide.

With more than 22 Innovation and Design Centers and factories worldwide, these advanced collaborative spaces are where we innovate new products, improve technologies, and partner with clients to design, test, and perfect their critical manufacturing processes.

OUR VALUES

Define Us

Innovation

Cultivating an environment of ingenuity will help us maintain a pioneering edge.

Compassion

Excellence

Quickness

We aim to achieve substantial growth as a business by promptly leveraging opportunities as they become available.

Partnership

Collaborating as a team will yield greater synergy and optimize efficiency.

Integrity

Honesty and ethics are the cornerstone of all endeavors in our interactions with stakeholders.

Possible industrial applications for air compressors

Contributing up to 12% of total industrial electricity consumption, air compressors act as an unseen partner to virtually every sector.

Compressed air is essential for almost every object we interact with. Dentists use compressors, and they drive pneumatic tools in manufacturing processes like spray painting. Air compressors are also present in cement plants, wastewater treatment plants, and power stations, among other examples.

High-performance air compressors

We value the seamless operation of your production as much as you do. That’s why Fs-Curtis compressors are some of the most trustworthy equipment on the market.

Compressor systems with the most budget-friendly total cost of ownership

Air compressors are long-term assets that play a crucial role in industrial operations. On average, factories replace air compressors every 7-10 years, meaning the initial purchase cost is only a small portion of the total expenses over the compressor’s lifespan.

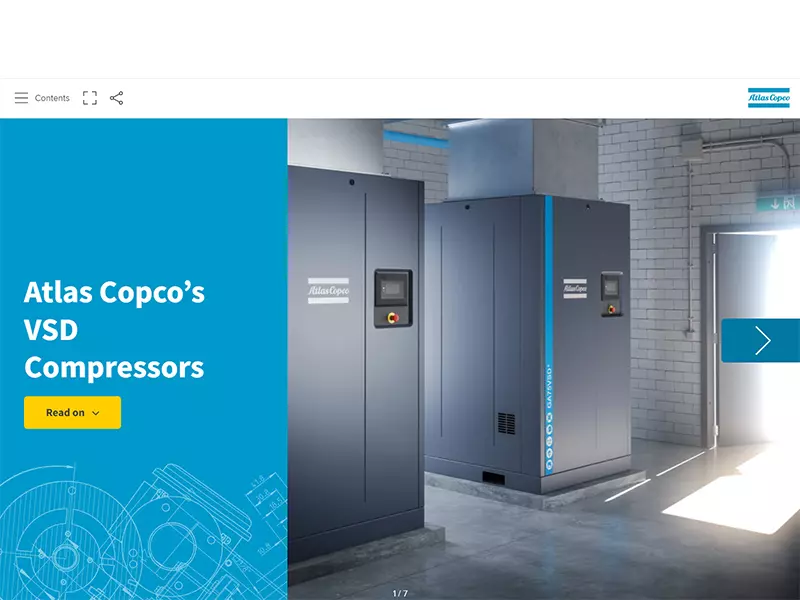

Our compressors offer the lowest overall ownership costs. Energy costs account for up to 80% of an air compressor’s total lifecycle expenses. Thanks to our continuously advancing designs and unparalleled energy-efficient variable speed drive (VSD) motors, we are able to minimize energy consumption. This leads to lower operational costs for you.

We offer Compressors, Air Treatment Devices, N2 and O2 installation that are personalized for your applications

What matters most to you? Factory layout? A silent compressor? Affordable finance solutions for your equipment? Full-service installation?

Our sales team will consider your requirements to recommend the ideal compressed air system for you. Whether you’re looking for the lowest initial investment as you’re starting out, or need a reliable compressed air installation with guaranteed uptime.

Submit Your Request And We Will Contact Your .

Learn more in our ebooks

E-book Rotary Screw Compressors

E-book rotary screw compressor comparison

Guide to selecting the optimal compressors

With so many models to choose from, which one is the right compressor for you? This guide will help you in making the right decision for your business.