Compressor Service and Aftermarket Care

CompAir offers a variety of solutions and services to help you control your costs, manage risk, and protect your investment.

Service /

The CompAir warranty and compressor service programs ensure the continued performance and efficiency of your system. High quality genuine spare parts not only prevent breakdowns but also keeps your compressed air network running at peak efficiency 24 hours a day, 7 days a week.

Why service your compressor with CompAir?

- Keep your compressor performing at optimum performance, regardless of the application

- Industry-leading, free-of-charge warranties and genuine quality spare parts and lubricants

- Air auditing, oil sampling and cloud-based analytics reporting on a global platform

- Increased reliability and plant uptime

- Minimal air losses contributing to energy savings

- Components manufactured within the strictest quality assurance systems

IES2 Efficiency

IES2: the gold energy efficiency standard for drive systems Where does IES2 come from? IES2 originally comes from the European Standard EN 50598, covering both Part 1 and Part 2. This has now been transferred to the International Standard IEC 61800-9,...

Compressed Air

Compressed Air Services from CompAir CompAir have been at the forefront of compressor design and manufacture for many years and are committed to quality and innovation. We are dedicated to understanding our customers' individual business goals and designing products...

Variable Speed Compressors for Improved Energy Efficiency

Variable Speed Compressors for Improved Energy Efficiency Energy efficiency is one of the most important factors all businesses are concerned with. The more efficient your air system, the lower your energy consumption and the cheaper your energy bill! A vast...

Lubricants

Air compressor oil and lubricants are a key component of any lubricated rotary compressor. Too often this vital element of the compressor package is misunderstood and under valued by the machine owner.

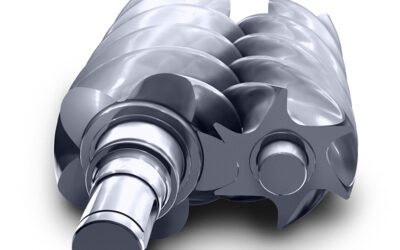

Rotary Screw Compressor Technology Explained

How do rotary screw air compressors work? When it comes to modern industrial machinery, the rotary screw compressor is one of the most widely used technologies. Renowned for their reliability and versatility, screw compressors are the workhorse behind many industrial...

Towable Compressors – Compressed Air on the Go

Towable Compressors - Compressed Air on the Go Compressed air is needed for many applications, often in industrial plants and warehouses. However, there are many times when compressed air is needed on building sites or other remote locations. For applications...

What is Compressed Air to Industries

Food and beverage industry Compressed air is used widely in the F&B industry for a range of applications starting with packaging processes as well as in conveying systems to move food and ingredients. Fluid pumps It is used in machines that...

Oil lubricated Air Compressor

Oil Lubricated Air Compressor Technology Lubricated Compressors Lubricated compressors require oil to keep the production process running smoothly. They are reliable and efficient compressors that can be installed alongside a variety of air tools and...

Fast and efficient aftermarket care

Our local service centres are staffed by factory-trained engineers and servicing is performed by our worldwide service network. Whether it’s installing custom-engineered turn-key solutions or carrying out professional air audits and reports, CompAir aftermarket care is efficient and reliable.

Aside from keeping your system operating reliably, a well-maintained air compressor will offer considerable energy savings as preventative maintenance helps to reduce the risk of breakdown. We offer a range of quality services to keep your system performing to the highest standard including:

Air audits

Whether you’re looking to install a new air system or just want to improve the performance of your current installation, an air audit is a great way to assess your compressed air equipment and gain a deeper insight into your air requirements and needs. We will provide a full report highlighting the results of the audit and offer advice to improve your energy efficiency. Find out more about our air audits by clicking here.

Ongoing monitoring with iConn

iConn is an online cloud-based system that allows users to monitor their air system using smart technology to provide real-time data and information. In-depth monitoring provides detailed insights and statistics about your air system. This can be a cost effective way to minimise downtime and maximise efficiency through preventative maintenance and early detection of faults. Learn more about iConn here.

Leak detection surveys

Leaks in your system can be extremely costly. Early identification of a leak can help to minimise damage and reduce expensive energy costs. Our technical support teams use ultrasonic leak detection technology to assess your installation and identify any leaks within the system. If any issues are identified, we offer a repair service to help get you up and running at peak performance again.

Oil sampling

We sample and analyse oil to identify any problems that may be at risk of occurring and any abnormalities within the system. Learn more about the benefits of oil sampling here.

Testing of pressure equipment

Pressure vessel tests are mandatory for plant owners. CompAir provides testing of pressure equipment, giving you a green light for your systems – and a safer working environment. Click here to read more about how we can help you to comply with current UK regulations.

We offer fixed price service on matters ranging from a simple inspection, checking for air leaks, diagnostic visits, full overhauls and a wide range of other checks. We have responsive and flexible maintenance agreements available, customised with your requirements in mind. To find out more, please feel free to contact us.