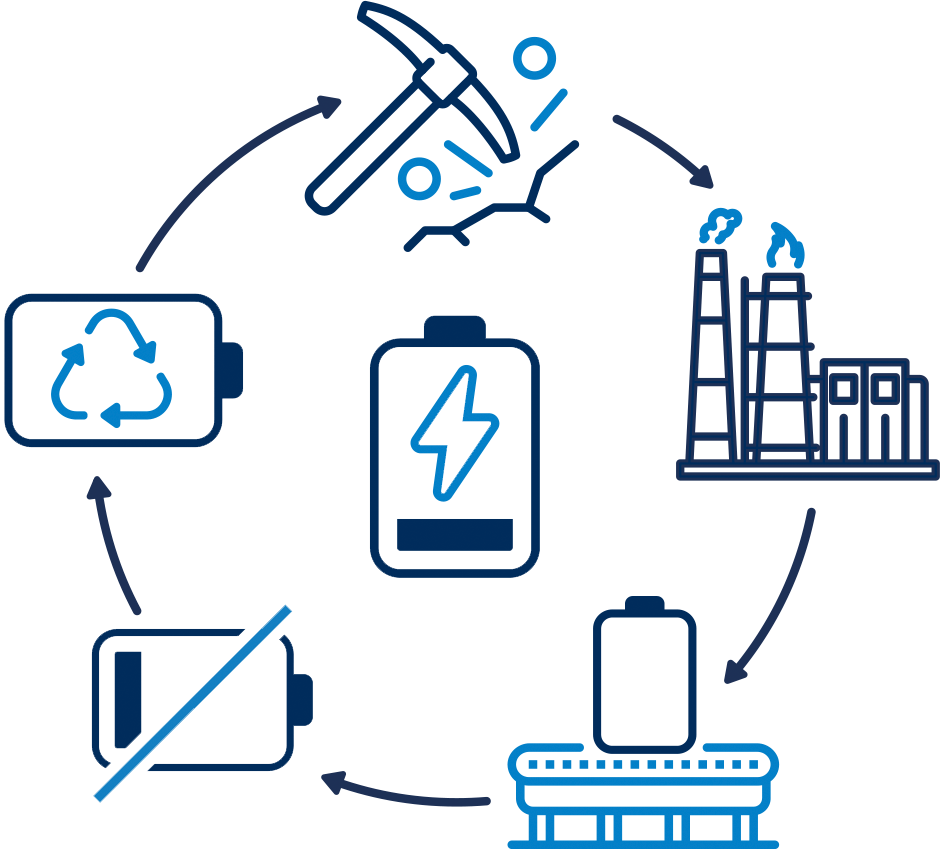

The Global Supply Chain of EV Battery Manufacturing

Before we get to the importance of compressed air in the EV and battery manufacturing industry, let’s first take a look at the global supply chain. The basic components of the electric vehicle battery manufacturing cycle include:

Upstream: This stage refers to the mining processes that take place to obtain new raw materials, such as lithium and nickel, that are used in creating the batteries.

Midstream: The raw materials collected are then refined and processed, which purifies them. This is called the ‘Midstream’ stage and enables the creation of anode and cathode battery materials. These materials are then sold on to firms that produce the battery cells.

Downstream: Next is the ‘Downstream’ stage of the EV battery manufacturing cycle. This refers to the battery manufacturers, who take these materials and turn them into the final product. They are then able to be put into the electric vehicles.

End of life: This is when the EV batteries no longer work or serve their purpose.

Reuse of Recycle: When the batteries reach their ‘End of life’, they can be reused or recycled; two sustainable methods to reduce waste and unsafe disposal.