Welcome to our new Service Expertise section

This new section to the CompAir website acts as a comprehensive guide to servicing and maintaining your compressed air installation. The different sections below show you how to keep your installation running at peak efficiency. There are simple guides and basic information ranging from replacing air filters to air ends, how to avoid leaks which cost you money, there are basic equipment checks and details about how smart monitoring of your system with iConn can help you prevent equipment downtime before it happens. We also have a comprehensive service schedules guide where you can download the service schedule for your machine.

Please select an option below:

Air Compressor Filter

learn how important air filters are to keep your air installation running at peak efficiency

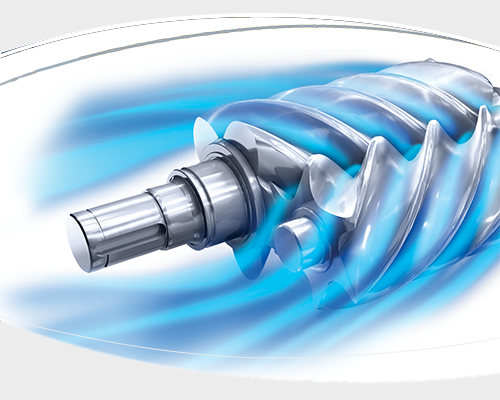

Airend Replacement

Using a genuine CompAir air end guarantees that your compressed air system will operate reliably and efficiently.

Avoid Leakages

Four good reasons why you should treat compressed air leaks like a dripping tap

Compressor Service Schedules

Important checks to make to keep your installation running at peak efficiency

Dryer Maintenance

Maintenance and leak tests for refrigeration dryers

Air Audits

To improve the energy performance of your existing installation, a great way to start is to carry out a compressed air audit.

AssureCOMPLETE

AssureCOMPLETE provides the highest equipment reliability and return on your maintenance budget

Pressure Equipment Check

Testing of pressure equipment – a green light for your systems plus a safer working environment

AssurePLAN+

AssurePLAN+ provides predictable, on-time planned services including diagnostics to catch potential problems, beforethey result in larger headaches.

Lubricants

Air compressor oil and lubricants are a key component of any lubricated rotary compressor. Too often this vital element of the compressor package is misunderstood and under valued by the machine owner.

Assure Service Agreements

The maintenance and protection of compressors is crucial for a manufacturing company

Oil Sampling

Oil Sampling and analysis can identify problems in the earliest stages which can keep downtime to a minimum, reduce repair cost and ensure optimum energy efficiency.