Save money, save energy and reduce your carbon footprint

Why heat Recovery

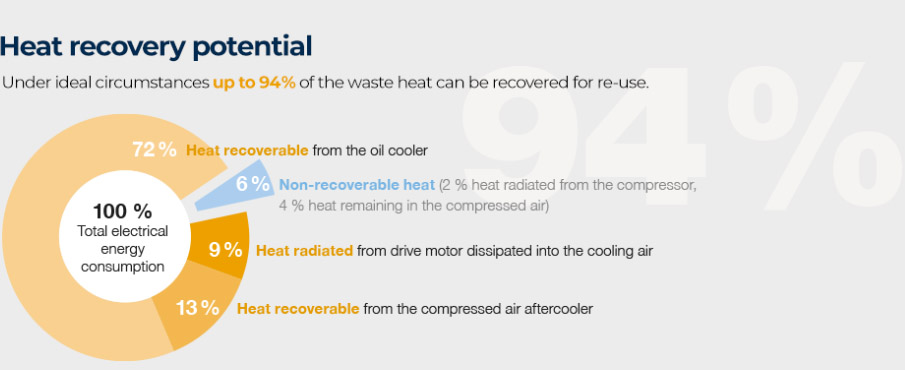

It is a thermodynamic fact that around 94 % of the energy needed to run a compressor gets converted to heat. Without heat recovery, this heat is directly blown into the atmosphere.

The heat generated during compression is paid for as part of the process, then it creates additional costs as this heat needs to be removed by cooling fans. At the same time, most companies consume a lot of energy and money to generate hot process water, space heating or preheat water for steam generation.

Given that compressed air systems account for 10% of all electricity used in industry, and energy is the largest single lifecycle cost of a compressor, it makes sense to recover this heat, save energy and reduce costs.

It’s critically important that we focus on energy now and in the future:

Give your compressed air system an efficiency upgrade

With heat recovery system from CompAir, the heat generated by the compressor can be re-used, providing the following BENEFITS:

- Significant savings in energy costs

- Short payback time – low investment costs payback time typically less than 1 year

- Lower CO2 emissions

- Turnkey solutions

- Easy installation and operation

- Small ecological footprint

- High reliability

- No impact on the compressed air supply

CompAir heat recovery options

Instead of simply removing the heat from the airend, it can be used to generate free hot process water or supplement hot water heating systems by utilising a high-efficiency oil-water heat exchanger – factory fitted, retro fitted or as a CompAir energy recovery box.